Curtain Wall Spandrel Panel Detail Things To Know Before You Get This

For skyscraper construction indoor glazing is in some cases used as a result of accessibility and logistics of changing glass from a swing phase. In outside polished systems, glass as well as opaque panels are mounted from the exterior of the drape wall surface. Outside glazed systems need swing stage or scaffolding accessibility to the exterior of the drape wall surface for repair work or replacement.

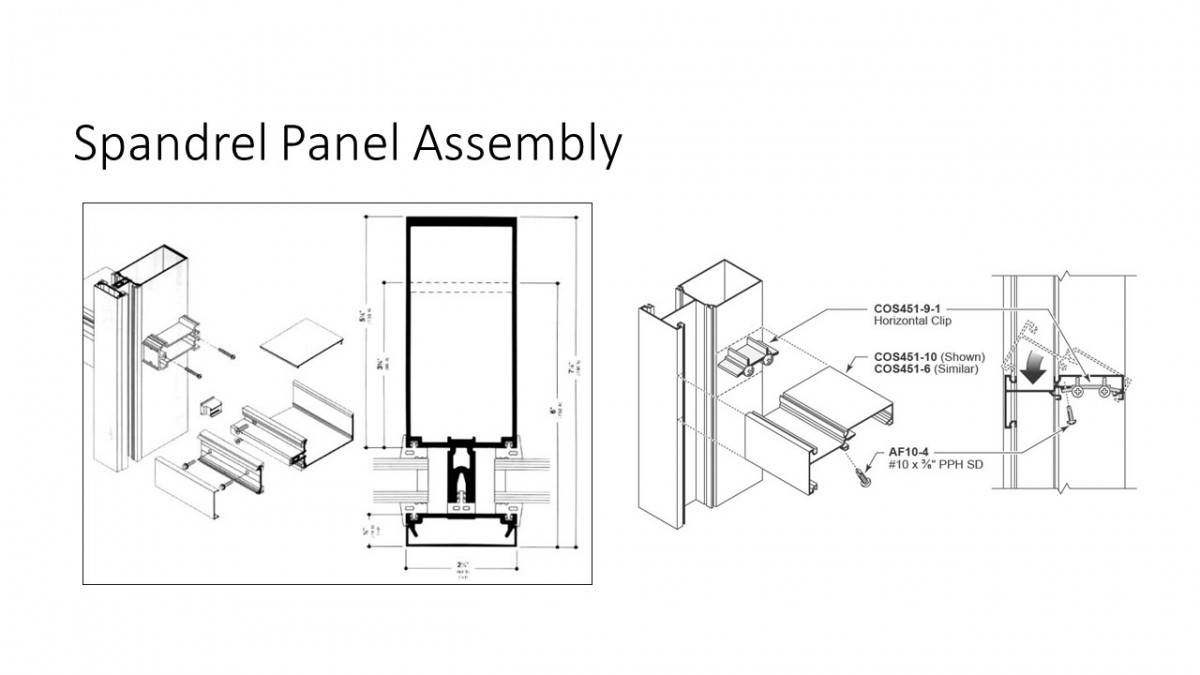

Common nontransparent panels consist of opacified spandrel glass, steel panels, slim rock, as well as various other products, such as terra cotta or FRP (fiber-reinforced plastic) (aluminum spandrel panel). Vision glass is mostly shielding glass and also may have one or both lites laminated (see Glazing), generally dealt with but in some cases glazed right into operable window structures that are integrated right into the drape wall surface framing.

The spandrel glass can be made opaque with using opacifiers (film/paint or ceramic frit) used on an unexposed surface or via "darkness box" construction, i.e., offering an encased room behind clear spandrel glass. Shadow box building creates a perception of depth behind the spandrel glass that is in some cases wanted.

Thin rock panels are most frequently granite. White marble ought to not be used due to its vulnerability to deformation because of hysteresis (thin stone is not covered in this chapter). The drape wall surface usually comprises one component of a structure's wall surface system. Careful integration with adjacent components such as various other wall surface claddings, roof coverings, and also base of wall surface details is needed for a successful installment.

Unknown Facts About Insulated Metal Spandrel Panels

Generally, pressure-equalized rainfall display systems offer the highest degrees of resistance to air and water infiltration, with water-managed systems the following most dependable. Pressure-equalized rain screen systems operate by blocking every one of the forces that can drive water throughout an obstacle. See the short article on Wetness Security for a complete description of just how pressure-equalization resists water passage.

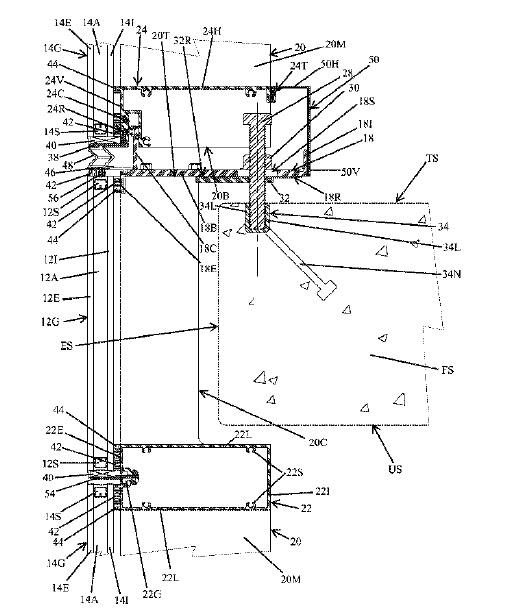

The outside face of glass, exterior glazing materials and the external revealed face of light weight aluminum framing function as a rain display, losing water away. Between the external rainfall screen and also the indoor air barrier a pressure-equalization chamber is created in the glazing pocket, which offers to decrease water penetration by removing (matching) the stress distinction across the rainfall display that tends to force water into the system.

Water-managed systems show up similar initially glance, incorporating drains and also weeps from the glazing pocket, yet no initiative is made to develop an air barrier or "zone-glaze" each glass or spandrel system, and for that reason a larger quantity of water is pushed into the system and also must be weeped away. Also, because no air obstacle exists, the pressure differential in between the glazing pocket and also the interior may be solid enough to require water up and down more than interior gaskets, resulting in leakages.

Crying of water is just a second feature. Note that the most convenient method to identify a pressure-equalized rain screen system is yo note that the that polishing pocket around each private unit of glass is separated air tight from adjacent devices, many obviously with plugs or seals at the spaces in between screw splines at mullion junctions.

Excitement About Curtain Wall Spandrel Panel Detail

Some light weight aluminum curtain wall systems are still created as face-sealed obstacle wall surfaces. They depend on constant and also excellent seals between the glass devices as well as the structure as well as in between all structure members to do. The long-term dependability of such seals is very suspect and also such systems need to be avoided. General curtain wall thermal performance is a feature of the polishing infill panel, the frame, building behind nontransparent (spandrel as well as column cover) locations, and also the boundary information.

thermal break). Light weight aluminum has a really high thermal conductivity. It prevails practice to integrate thermal breaks of low conductivity products, commonly PVC, Neoprene rubber, polyurethane and more lately polyester-reinforced nylon, for enhanced thermal efficiency. Some "put as well as debridged" polyurethane thermal breaks shrink and also worry kinds in the thermal break when the exterior light weight aluminum moves in a different way from the indoor aluminum because of temperature distinctions.

avoid debridging or "t-in-a box"). A real thermal break is" thick minimum and can be as much as 1" or a lot more, with the polyester strengthened nylon range. Some drape wall surface systems include separators that are less than ", making them "thermally enhanced". The much deeper thermal breaks can improve thermal performance as well as condensation resistance of the system.

These systems frequently include gaskets that are positioned in between the stress bar as well as mullions and function as thermal breaks and also aid with acoustic seclusion. These systems need special treatment in layout as well as building and construction to make sure connection of the gaskets at horizontal and vertical shifts (insulated spandrel panel detail). Gaskets are likewise made use of to cushion the glass on the exterior and interior faces of the glass.

Getting The Kawneer Spandrel Panel Metal Spandrel To Work

There is usually a gap in the gasket at the edges after contraction happens. With a properly designed system the water that enters the system at the gasket corners will certainly weep out via the breeze cover weep openings. To minimize contraction of gaskets back from the corners the use of vulcanized edges as well as diagonally reduced splices are advised.

Due to the absence of interior air beside nontransparent drape wall surface locations, these locations go through broad swings in temperature and humidity as well as require careful describing of insulation as well as air/vapor obstacles to minimize condensation. Some curtain wall surface systems consist of condensation drain stipulations, such as condensate seamless gutters, that are intended to accumulate and also weep condensate from spandrel areas to the outside; such condensate gutters and weeps are a violation of the air barrier of the drape wall unless they are outboard of the backpan.

At the curtain wall surface boundary, keeping continuity of the air obstacle lowers airflows around the drape wall. concrete spandrel panel. Combination of perimeter flashings helps make sure watertight performance of the curtain wall surface and also its link to nearby wall elements. Proper positioning of insulation at the curtain wall border decreases power loss as well as prospective condensation problems.

Look At This go to the website look at more info